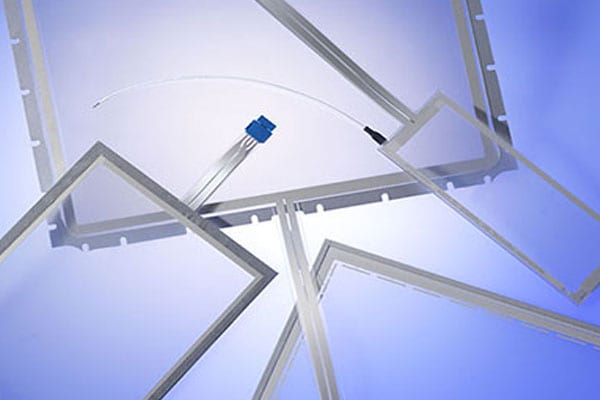

Options

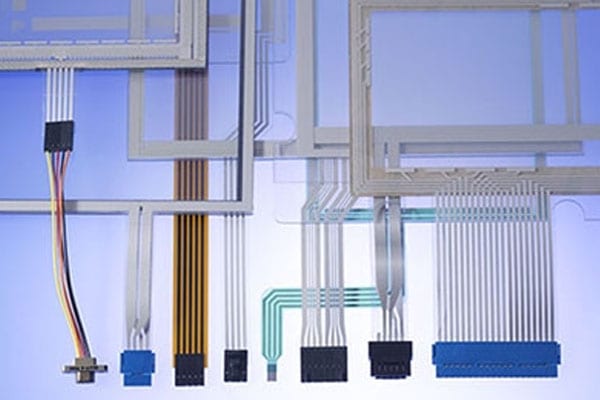

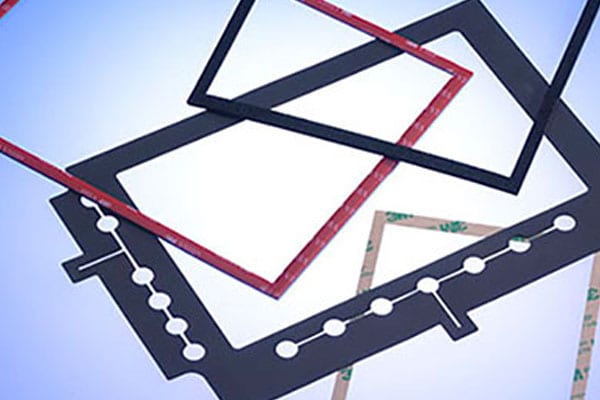

Not all touchscreens are created equally. TPI has an extensive background in design and manufacturing of projected capacitive and resistive touchscreens and years of exposure to various industries. This enables TPI to offer optimum design options to enhance a touchscreen’s performance, functionality and increase durability.